In the electrical sector, safety is paramount. A simple, inexpensive and effective device that ensures the protection of electrical circuits is the fuse. But exactly what is a fuse and what is its specific function? Let’s take a look together at when, where it is used and what are the various types available on the market.

Index:

- What is a fuse?

- What is a fuse made of?

- What is a fuse used for?

- Where and when is a fuse used?

- Fuse types

- Classification based on response speed

- Classification based on shape

- Colour codes for fuses

- Colour code with point

- Colour code with stripes

- Why is it important to understand what a fuse is?

What is a fuse?

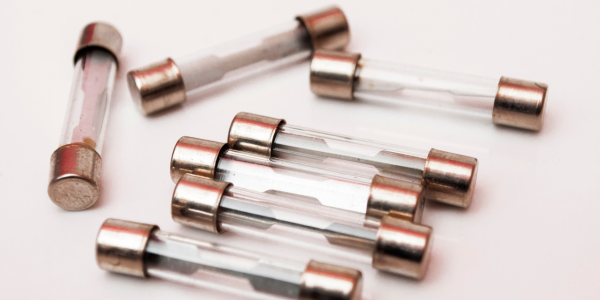

The fuse is a small safety device, found virtually everywhere there is an electrical system: in houses, cars, battery chargers, computers, ovens, etc.

It is a small but essential component, because its purpose is to protect an electrical circuit by interrupting the flow of electric charge in the event of overcurrent (overloads or short circuits).

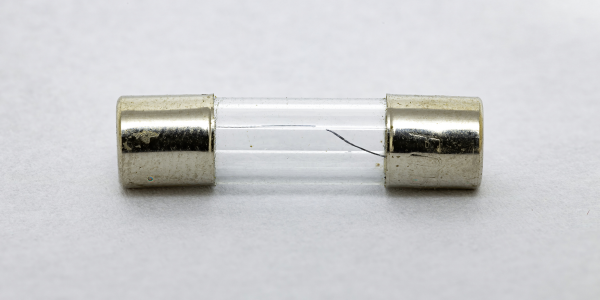

It consists of a metal filament or strip enclosed in an insulating casing: when the current exceeds a certain limit, the metal heats up rapidly until it melts, thus interrupting the circuit and preventing more serious damage.

What is a fuse made of?

A fuse, even if small and often hidden inside the devices to which it is connected, is designed in a simple and intelligent way.

It consists of:

- Body: this is the fuse casing. It can be made of glass, ceramic or heat-resistant plastic. It serves to contain and protect everything inside, while still allowing current to pass through.

- Metal filament: this is the core of the fuse. It is made of a metal that melts at a specific temperature (such as tin or silver). When the current exceeds the limit, the filament heats up and melts, interrupting the circuit.

- Connectors: the ends of the fuse that connect to the circuit. Designed to ensure good electrical contact.

- Sand or insulating material: only found in the most resistant fuses (especially those used in more powerful devices). It serves to absorb the energy of the electric arc that is created when the filament breaks, and to prevent sparks from forming or other elements from being damaged.

What is a fuse used for?

Let’s imagine that an appliance, such as an oven or washing machine, starts to draw more current than normal due to a fault. If there were nothing to protect it, the cables would overheat, melt or even catch fire. This is where the fuse comes in.

The main function of a fuse is to prevent damage to electrical systems and appliances and reduce risks to personal safety, such as fires or electric shocks. By promptly interrupting the electrical circuit in the event of overcurrent, the fuse protects cables, motors, electronic devices and other electrical components.

Where and when is a fuse used?

Fuses are used in many different contexts, such as:

- Domestic and industrial electrical systems: protect electrical lines and equipment against short circuits and overloads.

- Automotive sector: they protect electrical circuits in vehicles, preventing faults in lighting, audio and engine systems.

- Electronic devices and small appliances: prevent damage caused by sudden voltage surges.

In summary, the use of fuses is essential wherever it is necessary to protect equipment and circuits from potentially dangerous currents.

Fuse types

Fuses differ mainly in terms of response time and shape:

Classification based on response speed

- Rapid fuses (type F): They respond almost immediately and are recommended for the protection of sensitive electronic circuits.

- Slow or delayed fuses (type T): They temporarily tolerate initial current peaks (inrush currents), ideal for protecting devices with high initial power consumption such as electric motors or transformers.

Classification based on shape

- Cylindrical fuses: commonly used in civil and industrial electrical systems.

- Blade fuses: mainly used in the automotive industry.

- Cartridge fuses: suitable for high current applications.

Colour codes for fuses

Fuses often have dot or stripe colour codes that make it easy to identify their nominal current.

Colour code with point

The code with point consists of a single coloured dot on the end of the fuse, facilitating quick identification of the nominal current value.

| Colour | Nominal current |

| Red | 10 A |

| Blue | 15 A |

| Yellow | 20 A |

| Green | 30 A |

Colour code with stripes

The colour code with stripes has coloured bands that quickly identify the specific characteristics of the fuse.

| First stripe (nominal current) | second stripe (features) |

| Brown (1 A) | Red (fast) |

| Black (2 A) | Orange (slow) |

| Orange (5 A) | Blue (moderate speed) |

| Red (10 A) | Green (high voltage) |

| Blue (15 A) | White (low voltage) |

Choosing the right fuse, easily recognisable thanks to colour coding, ensures not only safety but also rapid intervention in the maintenance of electrical systems.

Why is it important to understand what a fuse is?

Choosing the right fuse to install, knowing its characteristics and how to identify it by colour codes, affects the safety and durability of the systems. Effective and timely maintenance of fuses ensures the reliability and longevity of electrical systems, significantly reducing the risks associated with electrical faults.

Discover the selection of electrical system fuses available on Elettronew.com.

You might also be interested in: